Want more detailed information?

Download our DynamiQ-S brochure for a deeper understanding.

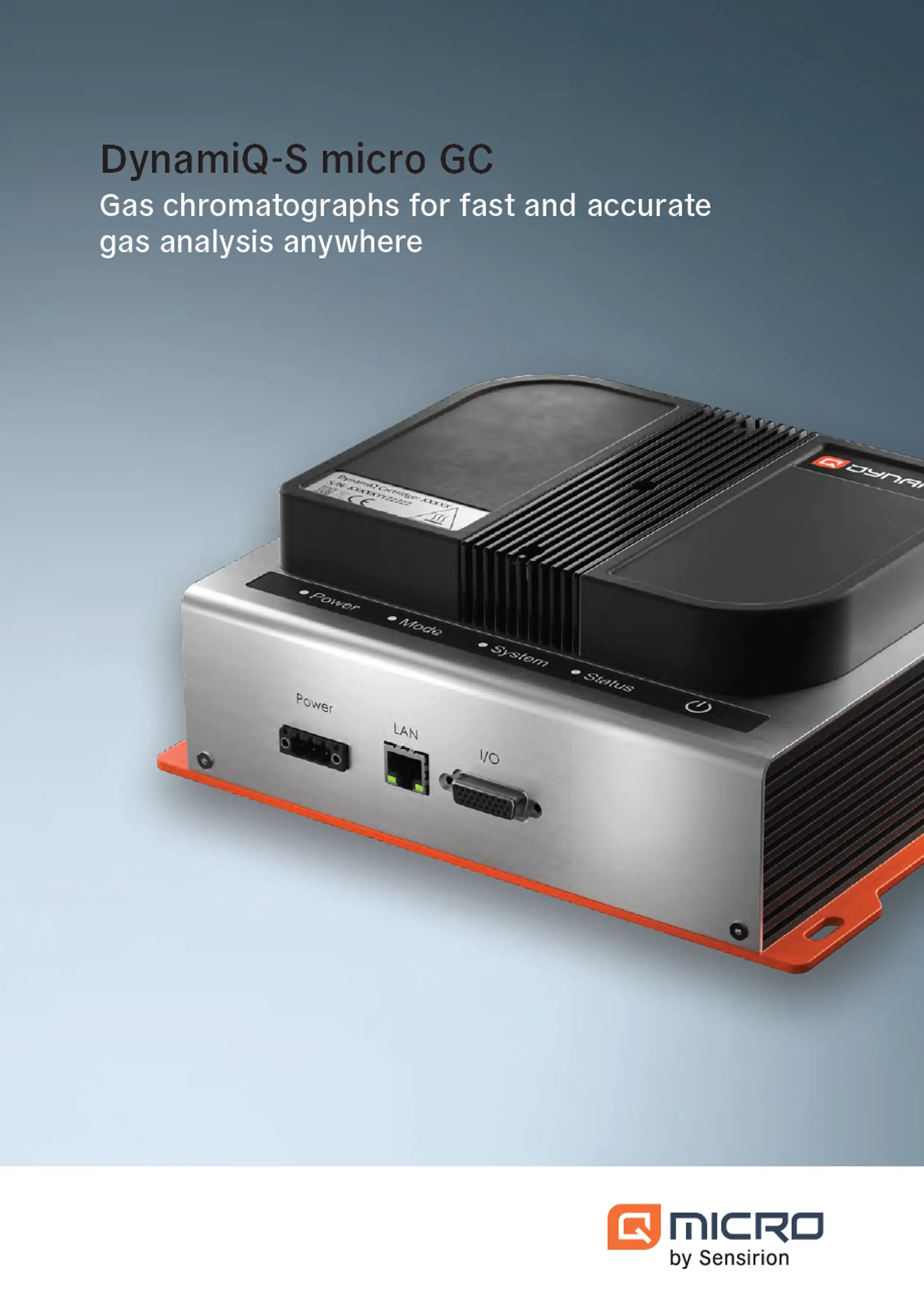

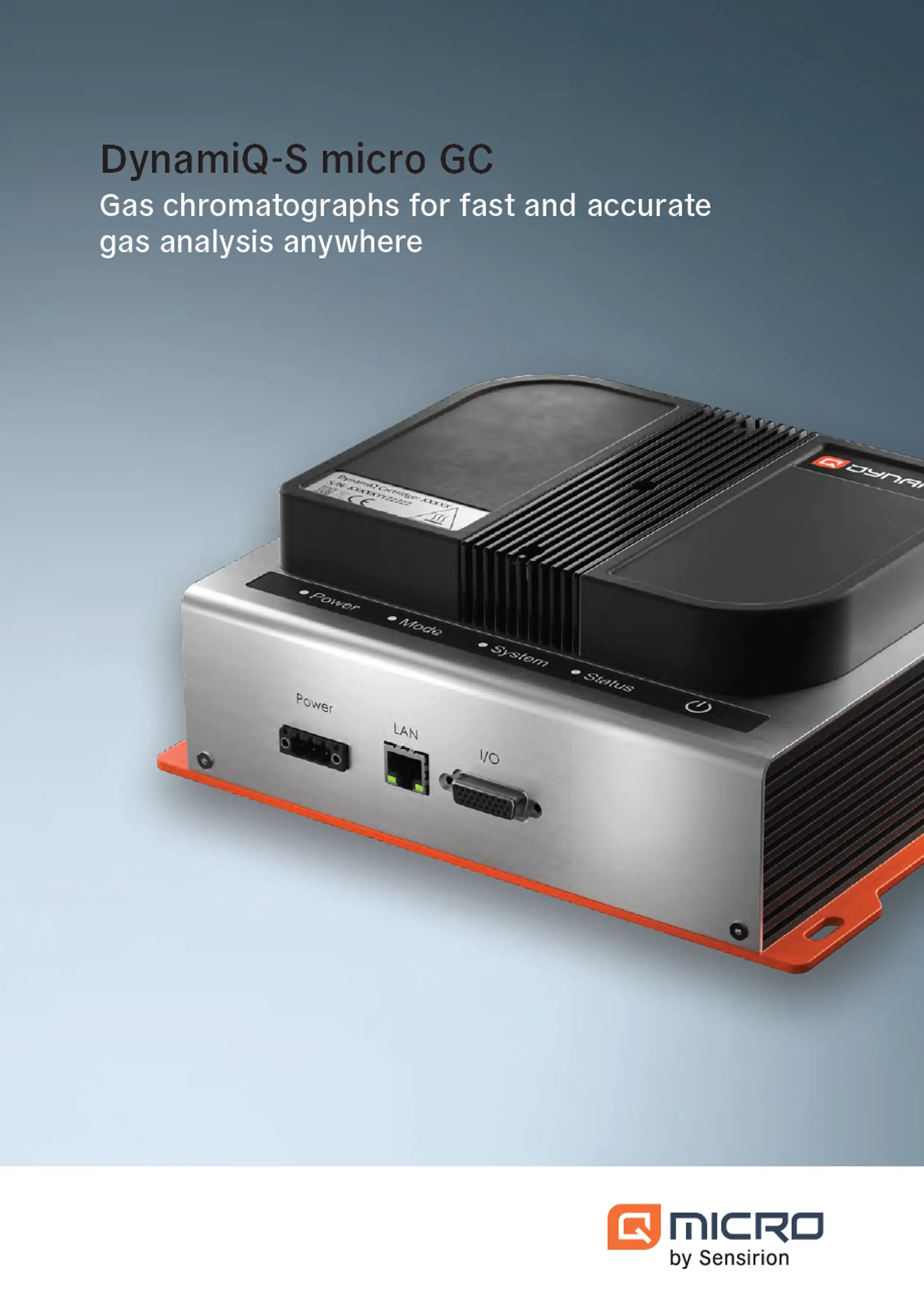

The micro Gas Chromatograph instrument is designed for continuous gas mixture monitoring in industrial process and factory automation applications. It can be custom configured in hardware and software to optimize the application. The instrument delivers a complete gas composition analysis in just 30 seconds. Utilizing backflush-to-detector technology, it enables simultaneous foreflush and backflush analysis while safeguarding the GC column for enhanced durability and performance.

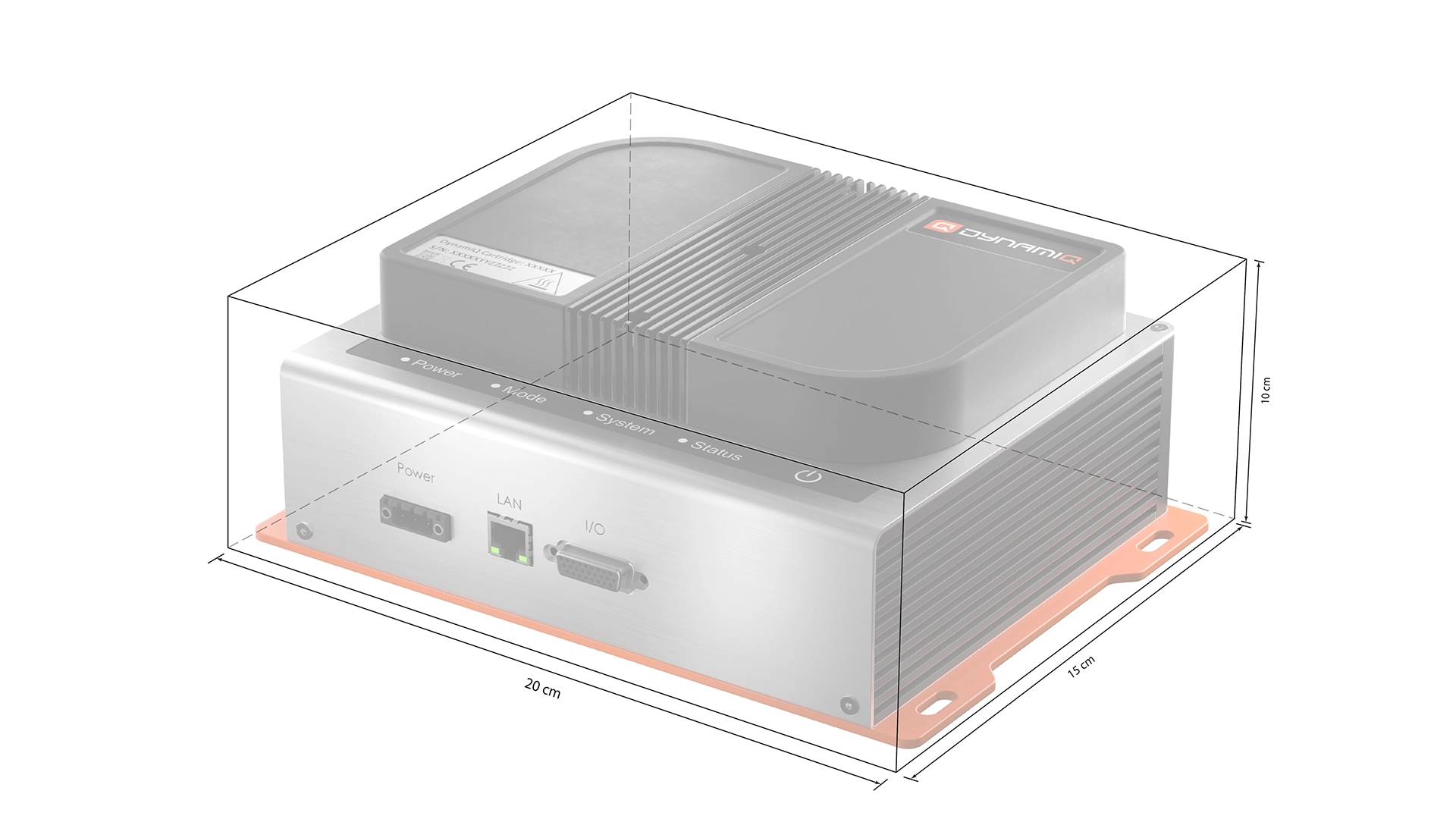

Easy to mount in enclosures. The DynamiQ-S contains a bottom plate with mounting holes for this purpose.

For simple and easy maintenance, each instrument is equipped with an easily replaceable cartridge, containing 1 to 4 GC units with the analytical parts. There are no tubes or capillaries in the instrument which enhances the robustness.

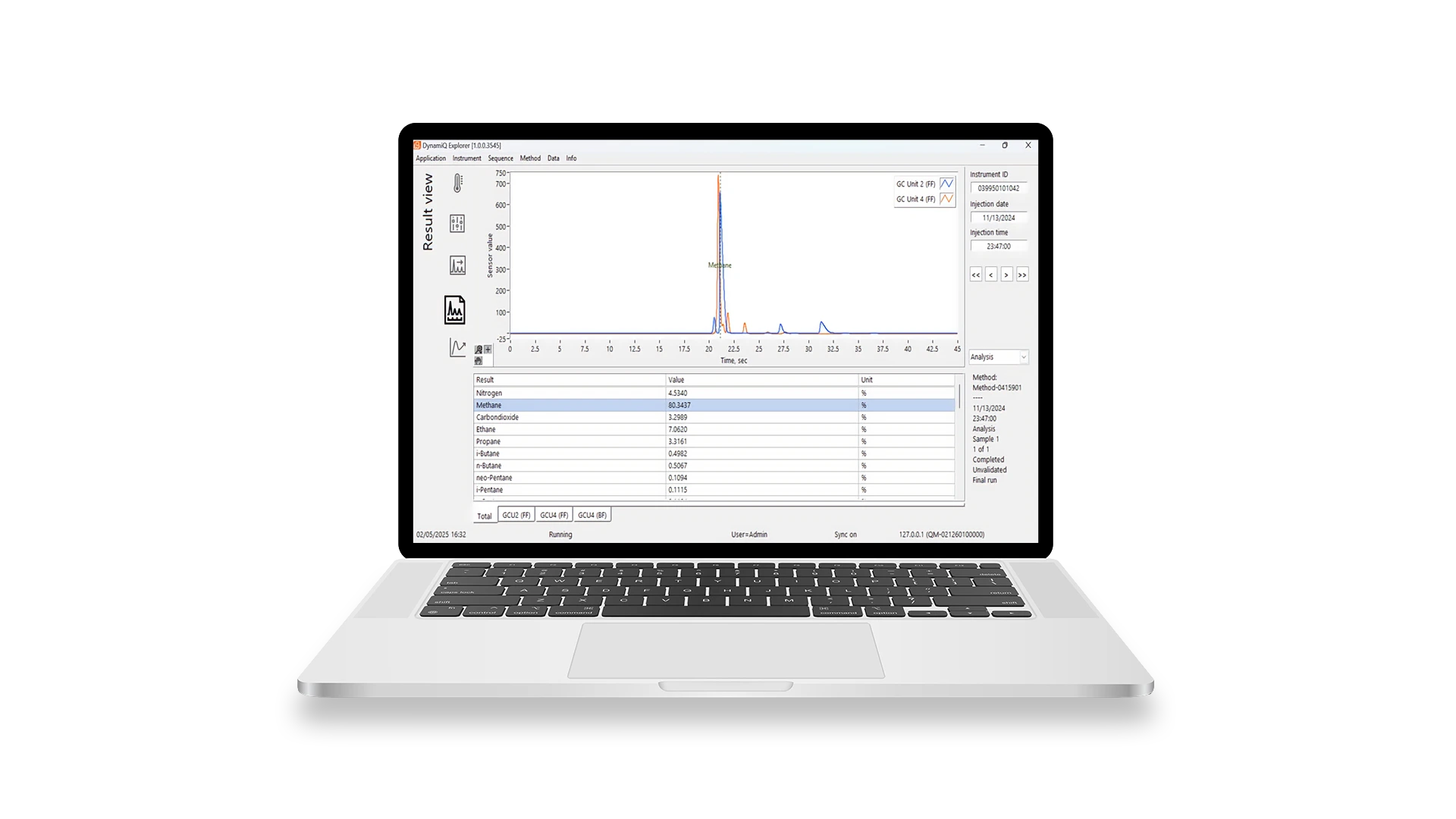

Continuous operation in industrial mode or laboratory mode. The user-friendly PC software, DynamiQ Explorer, provides users with full control.

Download our DynamiQ-S brochure for a deeper understanding.

Download our DynamiQ-S brochure for a deeper understanding.

Download hereExplore our videos and learn more about the DynamiQ-S gas chromatograph.